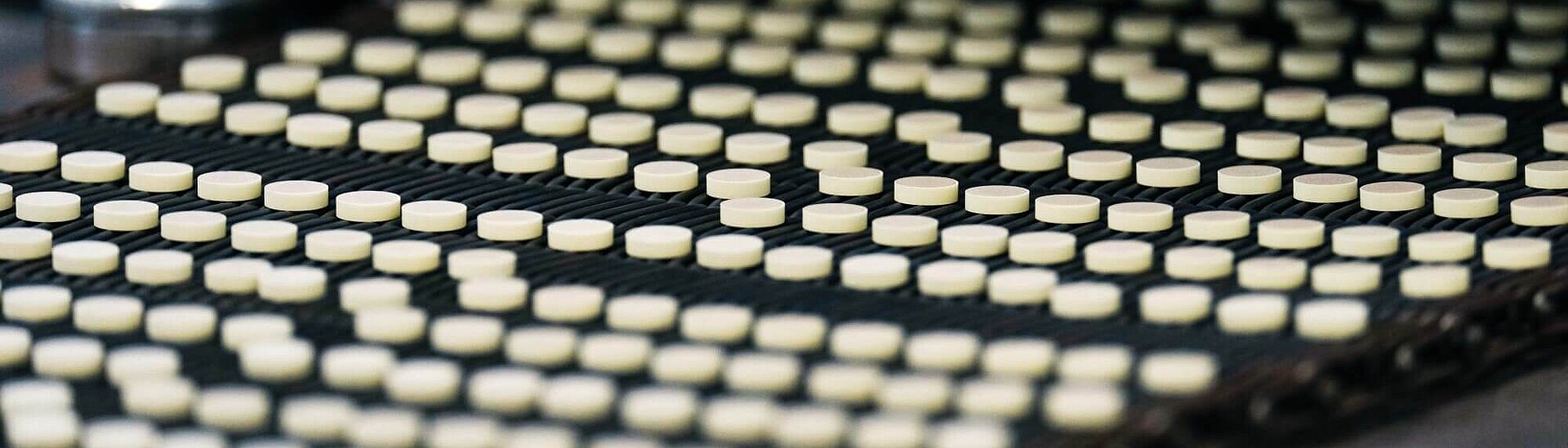

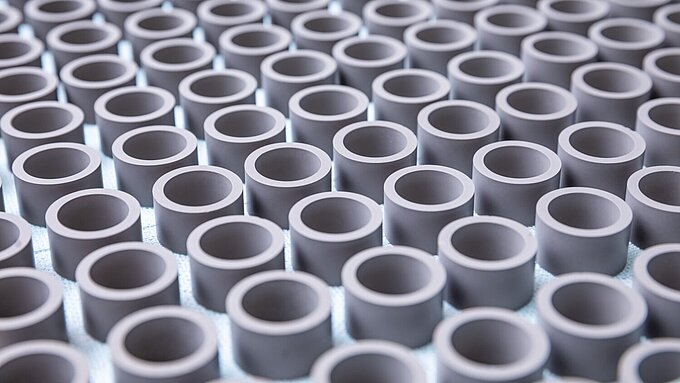

In the Piezo Components product division, multifunctional piezo ceramics are produced, starting at the manufacturing of the ceramic material. This high degree of added value is one of the unique selling points of PI Ceramic. Not only is the >> Multilayer product division provided with the base material for manufacturing the products but also all piezo ceramics for higher refinement in the >> Piezo Devices product division originate from our in-house production. Irrespective of the quantities, the automation of the product division ensures short delivery times as well as a consistently high level of quality.

Manufacturing Expertise from One Single Source

In all manufacturing steps, from the production of the >> materials and green bodies to the mechanical processing of the sintered bodies and metallization of the ceramic products, to the polarization and measurement of the electrical parameters, the manufacturing expertise is in the product division. The active key figure management (Shopfloor Management) ensures stability and quality in production – which is a decisive factor for partners in >> medical technology.

Automating manufacturing and increasing the corresponding level of digitalization gives the team the opportunity to better understand the manufacturing processes, take optimization measures, and apply new methods. With an automated production and digital data analyses, PI Ceramic can offer the continuously increasing quantities in the usual high quality and at marketable manufacturing costs, generating a real customer benefit. For this purpose, the product division uses simulation methods such as Plant Simulation and has modern equipment such as an inline sputtering plant, a pick-and-place system, and a fully automated measuring system.