PI Ceramic’s Piezo Devices product division manufactures customized assemblies for sensor and actuator technology applications, and also actuator modules and stack actuators – manufactured as high-voltage assemblies, as standard products or with customer-specific modifications. Many of these products, >> stack actuators and actuator modules in particular, act as assemblies for PI's piezo drives. All of the elements can be manufactured as single pieces in mid-sized and large batches, and also with customer-specific adjustments.

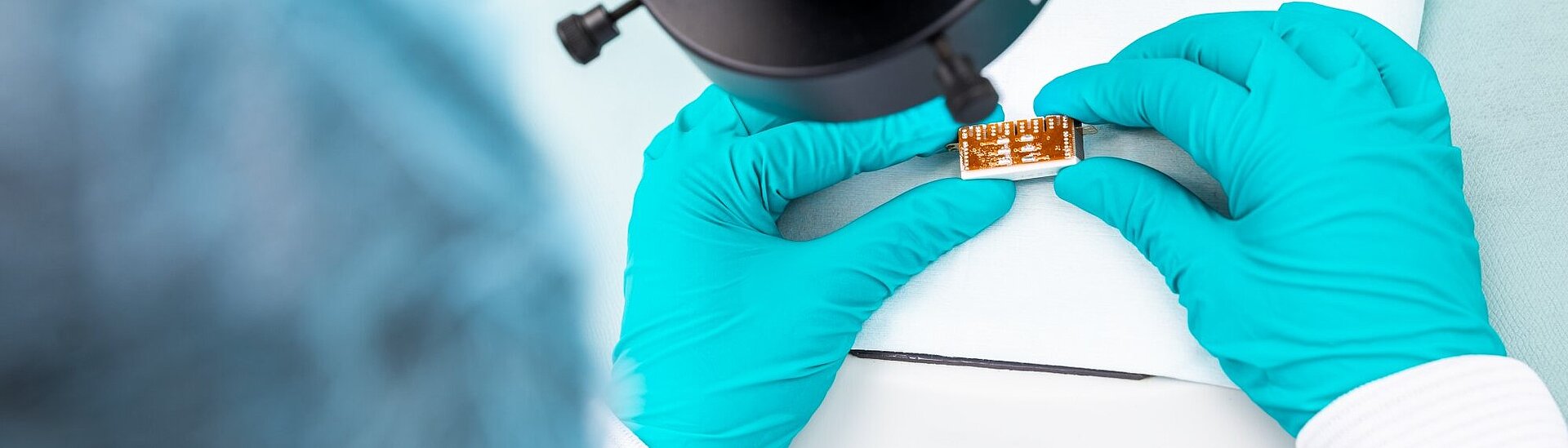

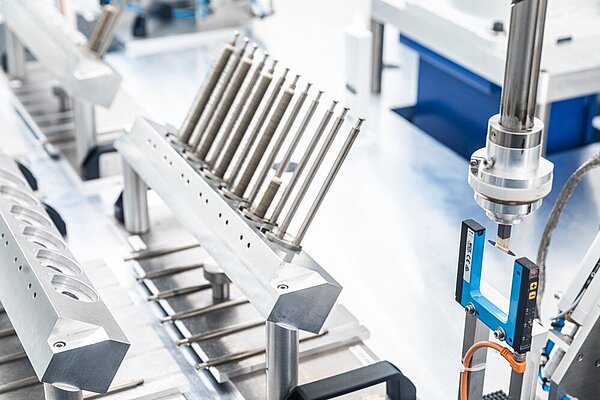

Automated and manual manufacturing processes under clean room conditions guarantee reliable product quality and short delivery times. At the same time, we can flexibly support our partners with different options for the application-specific usage of our piezo devices.

Supreme Product Quality and Scalable Manufacturing Depth

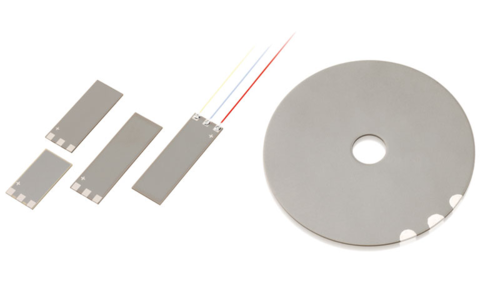

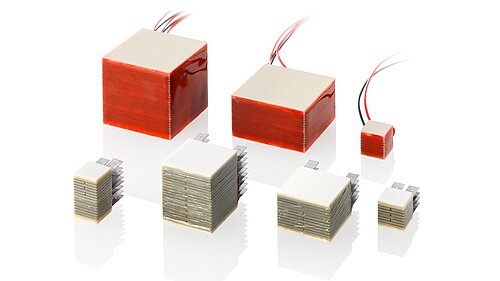

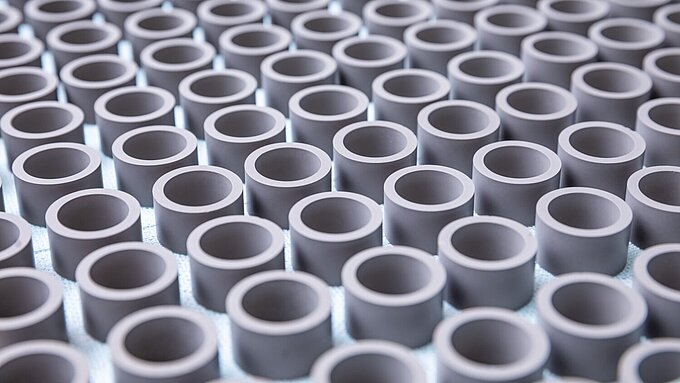

Amongst others, stack actuators have proven to be highly reliable for the semiconductor industry, micro and nano positioning, and for active vibration damping. To meet individual deflection and force requirements, they are assembled by stacking and gluing several piezoceramic elements like >> discs or >> plates together, contacting them electrically, and coating them with an external insulation layer made of polymer material. Depending on our partners’ requirements, piezo actuators can optionally be assembled with project-specific adjustments, e.g.

- Connecting cables for electric control in PI amplifiers or proprietary solutions

- Sensors for measuring the deflection for repeatable positioning in the nanometer range

- Temperature sensors for monitoring self-heating or third-party heating

- (Application-)specific tips for mechanically coupling the actuators, e.g., flat or spherical tips made of metal, ceramic, glass or sapphire

In addition to stacked actuators, PI Ceramic's standard product portfolio also contains >> shear and >> bending actuators.

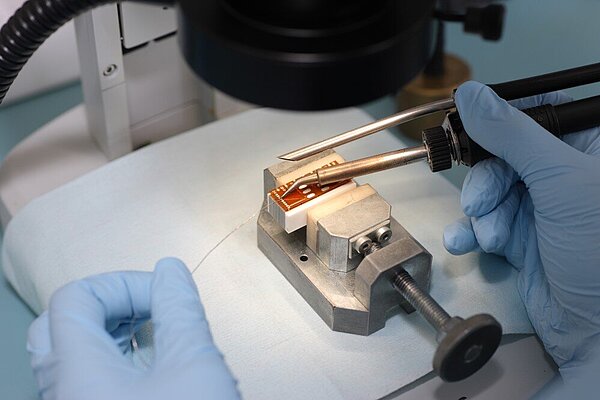

>> Gluing together piezo elements to make high-value assemblies is a critical step in the process, and has a considerable influence on the finished product’s characteristics such as total resonance frequency and stability. In mass production, the gluing and joining processes are automated for large quantities. To guarantee the consistent and high-quality dispensing of adhesives, the product division use their own dispensing and positioning systems for all products. The adhesive and the curing conditions are selected, optimized and monitored for the respective product and its material properties.

Integrating piezoceramic into our project partners' product can prove to be complicated, which is why PI Ceramic also offers complete solutions that can be directly integrated into the customer application. These so-called subassemblies are manufactured under clean room conditions. The product division’s experts take care of both the individual electric contacting of the elements, as well as their integration and assembly into the mechanical parts. For this reason, gluing and casting are also part of the standard refinement processes. For our customers, this speeds up integration into the final product, and in most cases, reduces the delivery times to the final customer.