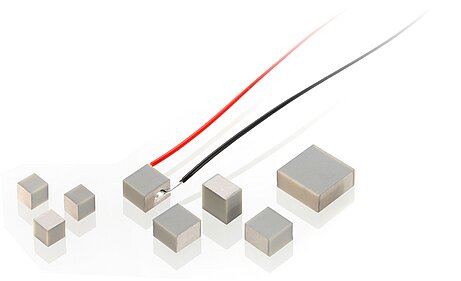

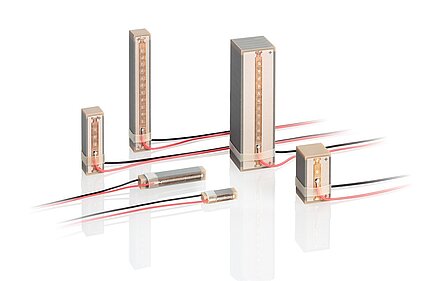

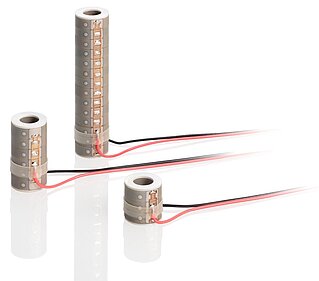

Piezoceramic >> tape technology is the core technology of the Multilayer product division. However, the depth of manufacturing goes beyond the piezoceramic multilayer components. This way customers profit e.g., from extensive assembly knowhow in clean rooms, for medical products or assemblies for the semiconductor equipment industry – with the highest level of quality assurance. The spectrum ranges from manual assembly and packaging, e.g., with tips, stranded wires, connectors, and >> flexible circuit boards under the stereo microscope to the fully-automated manufacturing of complex assemblies in large quantities.

Extensive Manufacturing Expertise for Best Quality and Long Lifetime

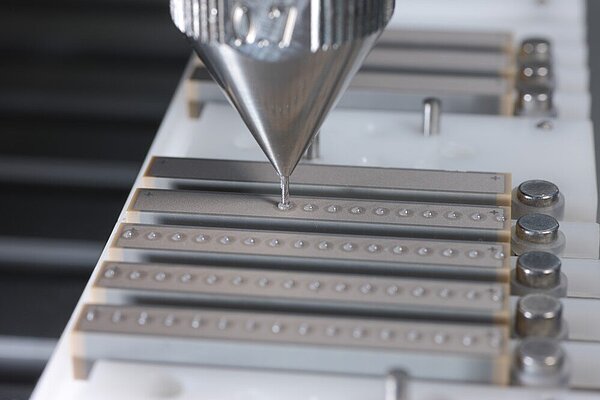

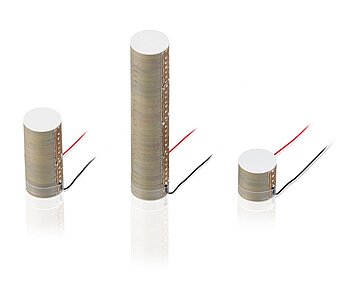

In the product division, multilayer components are created efficiently using the automated layering and laminating of individual, very thin layers, and the subsequent co-firing of the ceramic and the internal electrodes. Due to the thinness of the individual layers, they can be operated with very low control voltages. The usually all-ceramic insulation of the components guarantees outstanding lifetime and reliability.

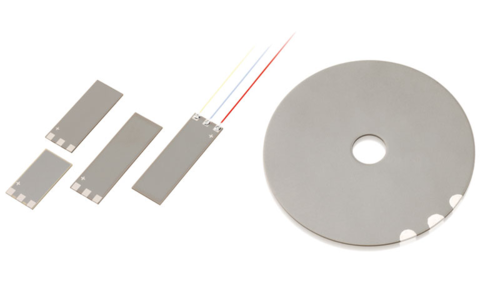

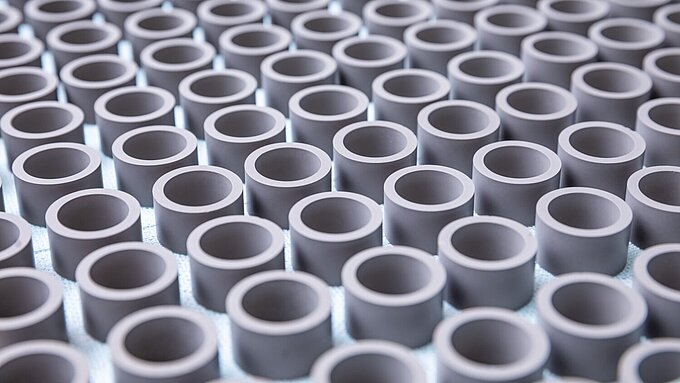

Flexible Quantities, Dimensions and Geometries

The Multilayer product division has various manufacturing routes. Together with the customer, this enables both the manufacturing of samples and products in small quantities and large series manufacturing. The high-precision manufacturing of the lateral dimensions using either automated structuring with extremely fine wafer saws, or using green or hard material machining in round geometries, corresponds with the thinness of the layer inside the components.